|

|

A GSF rotor mill (Glatt Sieve for moist

(Feucht) product) allows throughputs depending on the product

and process from 20kg to 5t/h.

|

|

|

|

Homogenization.

Of moist granulates after wet granulation. |

Crushing and milling.

Of agglomerates, lumps and compressed materials

to a defined maximum grain size. |

SC SuperClean® design

With the SC

SuperClean® concept, Glatt is offering a patented technology,

which sets the standard world-wide for cleaning. All sizes of Glatt GSF rotor

mills can be supplied in SC SuperClean® design for automatic cleaning

of the system (CIP). |

| |

|

|

Optimum product and process matching

- mobile (with carriage), height-adjustable, pivoting and railed designs

- 6 sizes

- 5 different rotor sizes

- 3 types of sieve insert with hole sizes 1mm to

20mm

- friction inserts for reducing large agglomerates

- stepless speed adjustment

- optimum sieve gap adjustment

|

|

|

|

|

|

|

PRO design

The PRO Concept

combines the highest safety levels (12bar pressure

shock resistance) with all the expectations of total containment. It ideally

complements all other systems in the Glatt PRO ranges |

|

|

|

|

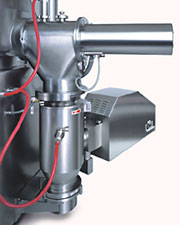

Glatt rotor mill

GSF 300 SC SuperClean®

traversably mounted

on rails, docked to the product

discharge of a vertical granulator |

|

Glatt rotor mill

GSF 180 SC SuperClean®

as a pivoting sieve on

the product discharge of a vertical

granulator |

| |

|